When it comes to home plumbing, there’s more than meets the eye. Behind the walls and under the floors lies a complex network of pipes, fittings, and connections, all working together to bring water to your faucets and remove waste from your home. A critical part of this system is the pipe connections, which ensure that water flows efficiently and safely through your house.

One term you may have come across is the IPS connection. But what exactly does it mean, and why is it important for homeowners? Whether you’re planning a plumbing upgrade or trying to troubleshoot an issue, understanding what the IPS connection is in home plumbing can make a huge difference. IPS, or Iron Pipe Size, is a standard used in plumbing systems to measure pipes, fittings, and connections.

Understanding IPS Connection in Home Plumbing

When discussing plumbing, you might hear the term IPS quite often. It stands for Iron Pipe Size, and it’s one of the most common standards for measuring pipes and fittings. But what does this really mean?

What is IPS?

The Iron Pipe Size (IPS) standard was introduced in the 19th century to create consistency in pipe manufacturing. Unlike some other measurement systems, IPS focuses on the outer diameter (OD) of pipes rather than the inner diameter (ID) or the threading. This standardization made it easier to produce and connect pipes across different materials, including iron, steel, brass, and PVC.

IPS vs. Other Sizing Systems

To truly understand IPS, it’s helpful to compare it with other plumbing standards:

- NPT (National Pipe Thread): While NPT refers to threaded connections, IPS measures the pipe size itself. However, many IPS pipes also use NPT threading.

- CTS (Copper Tube Size): Unlike IPS, CTS measures the inner diameter (ID) of copper pipes, which can make it confusing when comparing sizes.

Common Misconceptions About IPS

One common misconception is that IPS connections are only about threading. While threading is an important part of IPS, the term primarily refers to the consistent sizing system for pipes and fittings.

Materials Using IPS Standards

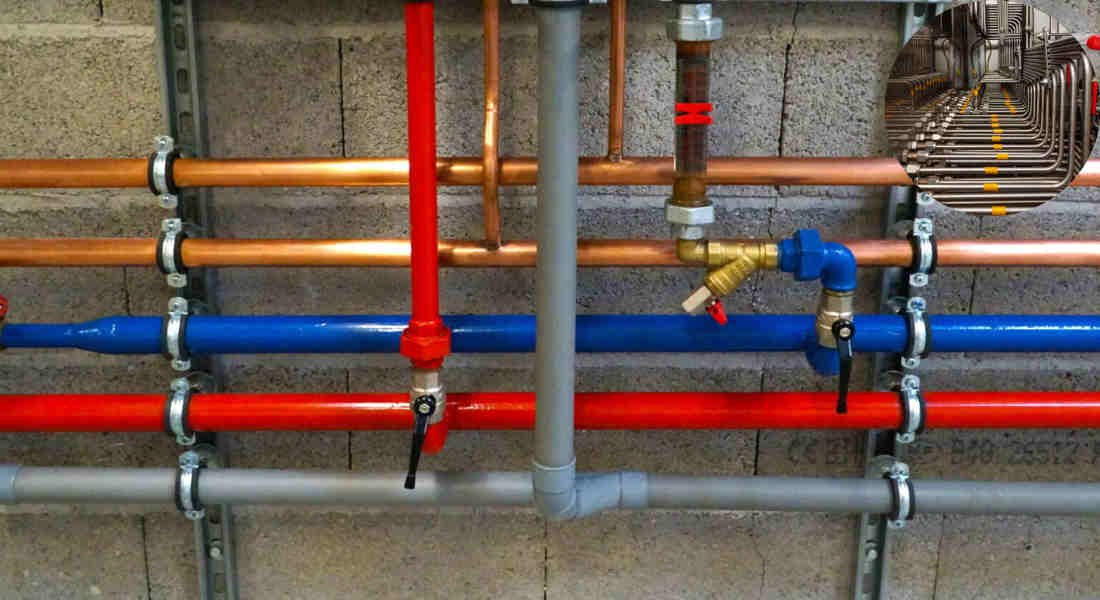

IPS is versatile and used across a variety of materials, making it a go-to standard for:

- Iron and steel pipes

- Brass fittings

- PVC pipes in modern plumbing

This versatility is one of the reasons why IPS remains a cornerstone of home plumbing systems.

How IPS Connections Work in Home Plumbing Systems

Understanding how IPS connections work can help you make informed decisions when installing or repairing your home plumbing system.

You may also read (5 key benefits of wet venting in home plumbing).

Threading Types in IPS Connections

IPS connections often involve threaded fittings, but there are two main types of threads:

- Straight Threads: These are mainly used for mechanical connections where the seal is created by a gasket or washer.

- Tapered Threads (NPT): These threads tighten as they are screwed in, creating a seal that prevents leaks.

Male and Female IPS Fittings

In plumbing, you’ll often hear terms like MIPS (Male Iron Pipe Size) and FIPS (Female Iron Pipe Size). These refer to the threading:

- MIPS fittings have external threads that screw into internal threads.

- FIPS fittings have internal threads that accept external threads.

Common IPS Connection Types

Here are some common IPS fittings you’ll find in home plumbing:

- Elbows: Used to change the direction of the pipe.

- Tees: Allow three pipes to connect at a single point.

- Couplings: Join two pipes together.

Sealing Methods

To ensure a leak-free connection, IPS fittings often require:

- Thread sealants: Such as Teflon tape or pipe dope.

- Gaskets or washers: For straight-threaded connections.

Compatibility Issues

While IPS is a standard, you may encounter compatibility issues when mixing it with other systems, such as CTS or NPT. Using the right adapters is crucial to avoid leaks or mismatched connections.

Advantages of Using IPS Connections for Homeowners

Why should homeowners care about IPS connections? Let’s explore their many benefits.

Consistency in Pipe Diameter

The IPS standard ensures a consistent outer diameter (OD), making it easier to plan and install plumbing systems.

Durability and Reliability

When installed correctly, IPS connections are known for their durability. They can handle high water pressures without leaking or failing.

Versatility

IPS works across various materials, including metal and plastic pipes, making it suitable for a wide range of applications.

Reduced Risk of Leaks

Thanks to their standardized sizing, IPS connections reduce the risk of leaks and pressure issues, especially when paired with high-quality fittings and sealants.

Ease of Maintenance

Because IPS fittings are widely available, replacing or upgrading them is relatively simple, saving time and money in the long run.

You may also read (unveiling the earnings of real estate house lawyers).

Common Applications of IPS Connections in Residential Plumbing

IPS connections are used in several areas of a home’s plumbing system. Let’s take a closer look at their most common applications.

Water Supply Lines

IPS pipes and fittings are commonly used for water supply lines, ensuring reliable water distribution throughout your home.

Drainage Systems

Drainage systems often utilize IPS-compatible pipes due to their durability and resistance to pressure.

Gas Lines

Many gas lines rely on IPS threading to create secure and leak-proof connections.

Outdoor Plumbing

From garden hoses to irrigation systems, IPS fittings are a staple in outdoor plumbing setups.

Common IPS Fittings

Here’s a quick overview of the IPS fittings you might encounter:

Fitting Type Use Case

Elbows Changing pipe direction

Tees Connecting three pipes

Couplings Joining two pipes

Adapters Transitioning between different standards

How to Identify IPS Connections in Your Home Plumbing

If you’re not sure whether your plumbing uses IPS connections, here’s how you can identify them.

Visual Cues

Look for markings like MIPS or FIPS on fittings. Additionally, measure the outer diameter of your pipes to see if they align with IPS standards.

Measuring Pipe Size

Use a caliper or ruler to measure the outer diameter (OD) of your pipes. This can help you determine whether they follow the IPS standard.

Comparing with Other Standards

Compare your pipes with CTS or NPT standards to confirm whether they conform to IPS.

When to Call a Professional

If you’re unsure, it’s always best to consult a licensed plumber to avoid potential mistakes or damage.

Tips for Homeowners: Installing and Maintaining IPS Connections

Proper installation and maintenance are crucial to maximizing the benefits of your IPS connections.

Installation Tips

- Use thread sealant or Teflon tape to prevent leaks.

- Ensure fittings are tightened correctly but not over-tightened, as this can damage threads.

- Use the right adapters when transitioning between IPS and other systems.

Maintenance Tips

- Regularly inspect IPS connections for leaks or corrosion.

- Replace worn-out gaskets or washers promptly.

- Flush pipes periodically to prevent buildup.

Common Mistakes to Avoid

- Mixing IPS with non-compatible systems without adapters.

- Over-tightening fittings, which can strip threads.

Safety Considerations

For gas lines, always ensure IPS connections are installed and inspected by a certified professional to prevent hazards.

You may also read (snake the plumbing).