Plumbing has come a long way from the days of clay and lead pipes used by ancient civilizations. Over time, the evolution of materials has transformed how water is delivered to our homes. From galvanized steel to copper and PVC, each material brought its own set of benefits and challenges. However, one material stands out as a revolutionary game-changer in modern plumbing—PEX (cross-linked polyethylene).

PEX plumbing has reshaped the industry with its unique combination of flexibility, durability, and affordability. It’s now one of the most widely used materials in residential and commercial plumbing systems. But have you ever wondered what year PEX home plumbing started? Understanding the origins of PEX not only satisfies curiosity but also illuminates why it’s become a favorite for both homeowners and professionals.

What is PEX Plumbing?

Defining PEX Plumbing

PEX, or cross-linked polyethylene, is a type of plastic tubing that has become a staple in plumbing systems worldwide. The term “cross-linked” refers to the chemical process used to enhance the material’s strength and durability. This makes PEX incredibly resistant to wear and tear, a key factor in its success.

Key Characteristics of PEX

PEX offers several standout features that differentiate it from traditional materials like copper or PVC:

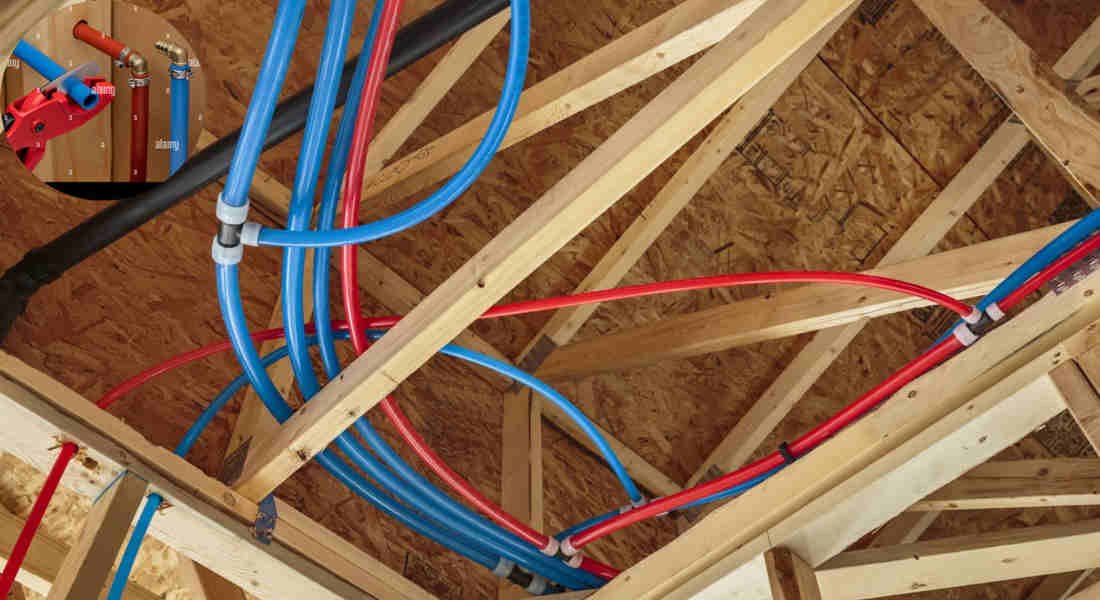

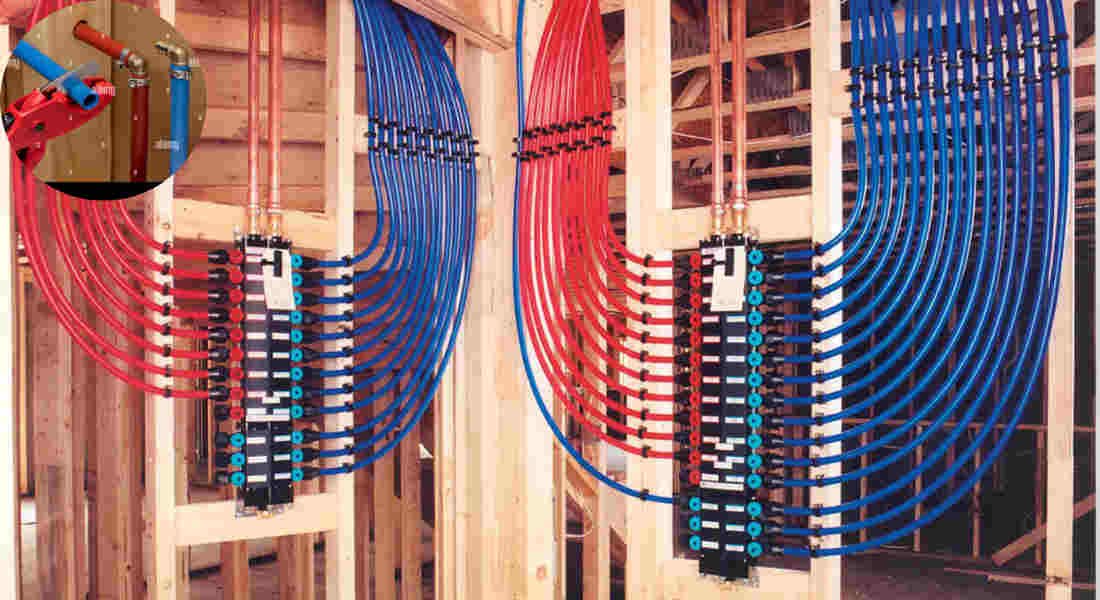

- Flexibility: PEX pipes can bend around corners, reducing the need for costly fittings and connections.

- Durability: The material is resistant to corrosion, scaling, and chemical damage, ensuring a longer lifespan.

- Temperature Tolerance: PEX can handle both hot and cold water applications without losing its integrity.

- Ease of Installation: Thanks to its flexibility and lightweight nature, PEX allows for quicker and more efficient installations.

Common Uses of PEX Plumbing

PEX plumbing is widely used in:

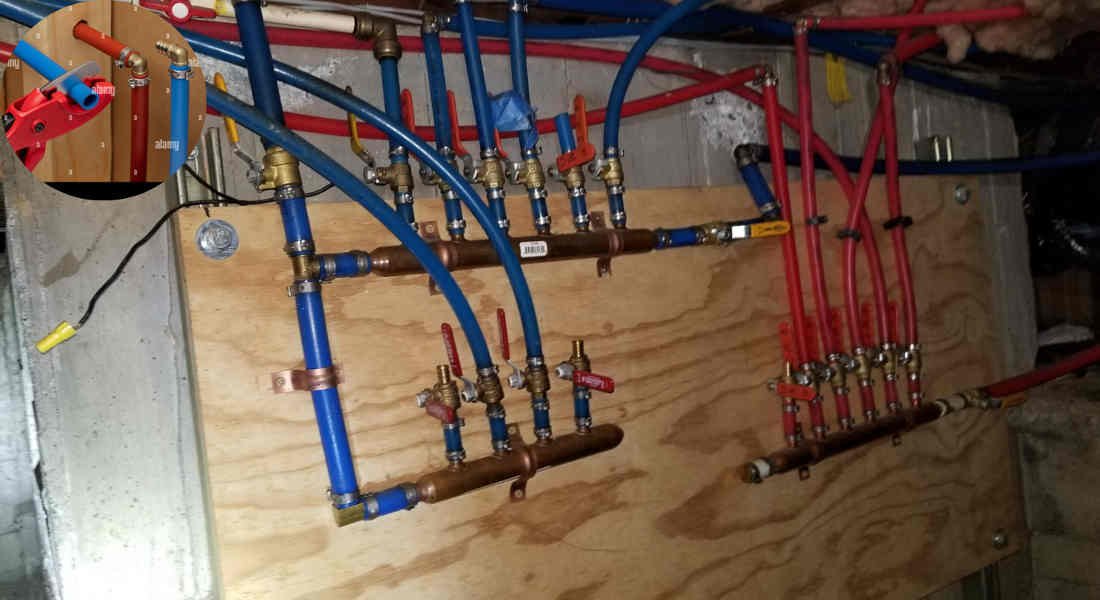

- Residential Plumbing Systems: For delivering hot and cold water throughout homes.

- Radiant Floor Heating: PEX tubes are installed within floors to distribute heat evenly.

- Snow/Ice Melting Systems: Used in driveways or sidewalks to prevent ice buildup.

- Commercial Applications: From office buildings to industrial facilities, PEX has a wide range of uses.

Comparison With Traditional Materials

FeaturePEXCopperPVC

Cost Lower Higher Moderate

Flexibility: Highly flexible, Rigid: Rigid

Corrosion-resistant Prone to corrosion Resistant

Installation Easier, fewer connections, requires soldering Moderate

Durability: Long lifespan. Durable but prone to damage. Moderate durability

The Origins of PEX Plumbing

The Birth of Polyethylene Plastics

To understand the origins of PEX, we need to go back to World War II, when the development of polyethylene plastics began. During the 1950s, advancements in polymer science pushed the boundaries of what plastics could achieve. Scientists experimented with ways to make polyethylene stronger and more resilient.

You may also read (clean plumbing pipes at home).

The Invention of Cross-Linking Technology

In the late 1950s, researchers developed a process called cross-linking, which transformed polyethylene into a stronger and more durable material. This breakthrough was pivotal in creating what we now know as PEX.

Thomas Engel and the Invention of PEX

The true turning point came in 1968, when German scientist Thomas Engel invented the first form of PEX tubing. Engel’s method involved using a high-pressure peroxide extrusion process to cross-link polyethylene. This innovation paved the way for PEX to become a practical and versatile material for various applications.

Initial Applications in Europe

Before PEX entered the plumbing industry, it was predominantly used in hydronic radiant heating systems in Europe. Its resistance to high temperatures and corrosion made it an ideal material for these applications.

Introduction of PEX Plumbing to the United States

PEX Arrives in the U.S.

PEX was introduced to the United States in the 1980s, where it was initially used for radiant floor heating and snow-melting systems. Its flexibility and efficiency were well-suited for these niche applications.

Expansion into Residential Plumbing

By the late 1980s and early 1990s, PEX began to gain traction in residential water piping systems. Homebuilders and plumbers started recognizing its advantages over traditional materials like copper, especially as copper prices surged during this period.

You may also read (plumbing stack at home).

Factors Driving Adoption

Several factors contributed to the growing popularity of PEX in the U.S.:

- Affordability: PEX was significantly cheaper than copper, both in terms of material cost and labor.

- Ease of Installation: Its flexibility reduced the need for fittings and made installations faster and simpler.

- Durability: PEX’s resistance to corrosion and scale buildup made it an attractive choice for long-term use.

Timeline of PEX Plumbing Adoption and Growth

Here’s a detailed timeline of PEX’s journey:

YearMilestone

In 1968, Thomas Engel invented PEX tubing in Germany.

1972: The first commercial production of PEX pipes began in Europe.

1980s PEX was introduced in the U.S., primarily for radiant floor heating applications.

1990s PEX gains popularity in residential plumbing due to rising copper prices.

1993 Commercial availability of PEX for U.S. plumbing markets begins.

In the mid-2000s, PEX became widely accepted as a standard material for plumbing and repiping projects.

Present PEX dominates the plumbing industry and is the most common repiping material in the U.S.

Benefits of PEX Plumbing Driving Its Popularity

Flexibility and Ease of Installation

PEX’s ability to bend and curve allows for installations with fewer fittings, reducing the chances of leaks and speeding up the process.

Durability and Longevity

Unlike copper, PEX doesn’t corrode or develop scale over time. This makes it a long-lasting solution for plumbing systems.

Cost-Effective

PEX is not only cheaper to produce but also lowers labor costs due to its simple installation requirements.

Freeze Resistance

PEX pipes can expand slightly when frozen, preventing bursts, a major advantage in colder climates.

How PEX is Manufactured: Cross-Linking Methods

Peroxide Extrusion (PEX-A)

This method involves using high-pressure peroxide to create a highly flexible and durable form of PEX.

Silane Extrusion (PEX-B)

A chemical process that uses silane compounds to cross-link the polyethylene. PEX-B is known for its affordability and moderate flexibility.

Electron Beam Cross-Linking (PEX-C)

This method uses electron beams to cross-link the polyethylene, resulting in a less flexible but equally durable PEX pipe.

Current Trends and Future Outlook for PEX Plumbing

Green Building and Sustainability

PEX is increasingly being used in eco-friendly construction projects due to its energy efficiency and recyclability.

Technological Advancements

Innovations in PEX manufacturing continue to improve its performance and ease of installation, ensuring its relevance for years to come.

Challenges Ahead

While PEX is highly popular, it faces challenges such as competition from newer materials and concerns about plastic waste in the environment.

You may also read (how to understand high home plumbing costs).